Casing Inspection

Before costly completion investment,

ensure casing integrity.

Over time, casings may be subjected to various stresses, such as pressure, temperature, and corrosion, which can potentially lead to degradation. Casing inspection involves the use of specialized tools and technologies to assess the condition of the casing. Eagle Reservoir is proud to offer casing inspection services to control risk, maintain the integrity of the well and longevity of production.

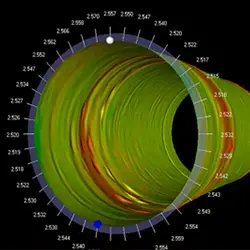

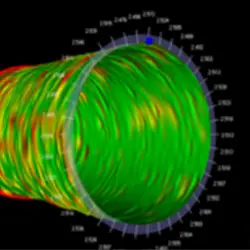

40 Arm Casing Calipers In Combination with Spinner/Temperature

- Thoroughly satisfy MIT requirements

- Determine wear and corrosion in casing very precisely

- Identify pits, holes, ring damage, drill wear by joint-by-joint analysis

- Conveyed in many ways (wireline, slickline, tractor, coil) and acquire data through memory or surface readout.

Interested in more Detail?

Download any of our example documents, presentations and graphics below

Casing Inspection Joint and 3D Example PPTCasing InspectionCasing Inspection 2